PANENERGEIA

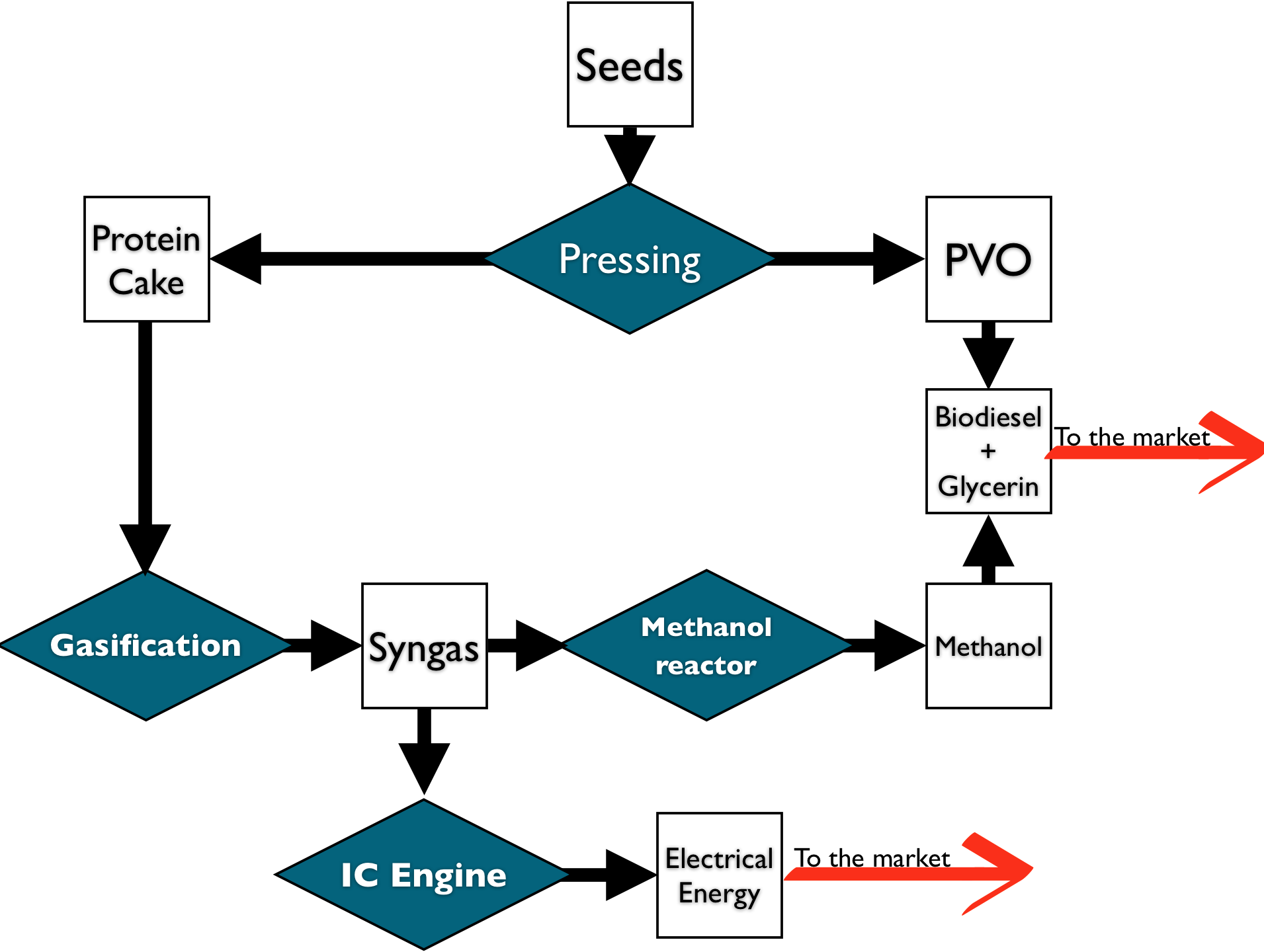

Figure 1: System layout

The project aims to convert the vegetable-oil to biodiesel production chain through an innovative method capable of integrating the extraction of vegetable oil with gasification processes for the production of bio-diesel and electricity. The aim is to create a system to get rid of carbon emissions related to raw and semi finished materials transportation, to facilitate the direct sale of energy and bio-diesel to the market and to eventually exploit all products and by-products from oilseed crops.

Basically, the core of the idea is to create high-tech rural areas where micro gasifiers, GTL systems and pressing facilities are coupled. The synergy between these technologies creates a system with higher overall conversion efficiency.

The system layout proposed here is represented in Figure 1: every year a different crop is cultivated and the seeds are converted into PVO by a mechanical process. The protein cake obtained as a by product of the oil extraction is gasified to syngas in a downdraft stratified reactor connected to an electrical generator of 10 kW peak power. A small part of the syngas is converted to methanol in a chemical reactor. The methanol is then used in the transesterification of the PVO to produce biodiesel.

The biodiesel production process is divided into two stages: first the syngas is converted into methanol then PVO and methanol are mixed in a second reactor with a catalyzing agent for biodiesel production.

The rotations change depending on the climate zone in the UE, i.e. most of Italy is suitable for rapeseed-sunflower-soy rotation.

As previously discussed, this work introduce an innovative method for biodesel production. It has several advantages here reported:

- The method can be applied to all the fields that cultivate oilseeds crop for biodiesel production

- Centralization of all the passages in biodiesel production: this work shows how is possible to concentrate the passages from field to biodiesel in the same plant. This solution reduces the transport costs and energy consumption.

- Centralization of all the passages in biodiesel production II: suppression of all the market middle-passages of the biodiesel supply chain. The system proposed guaran- tees direct sell of electrical energy into the grid and biodeisel to the market obtaining prices influenced by less factors

- The method give back the profits to the primary sector

- Distributed power generation from renewable sources

- This draft is based on a power output of 7-10 kW. It is produced from the biomasses collected by cultivating a surface of less than 15 hectares. This important result guarantees that the system is effective even for most of the farming companies without requiring to form consortium.

- On the other hand all the equations proposed can be scaled up to higher powers, so larger plants can be design without increasing the complexity of the system

These advantages have economical and social implications that need to be discussed case by case. In some cases, depending on fuel and energy costs as well as subsidies for renewable energy production, it will be better to self consume the electrical energy or the biodiesel produced.